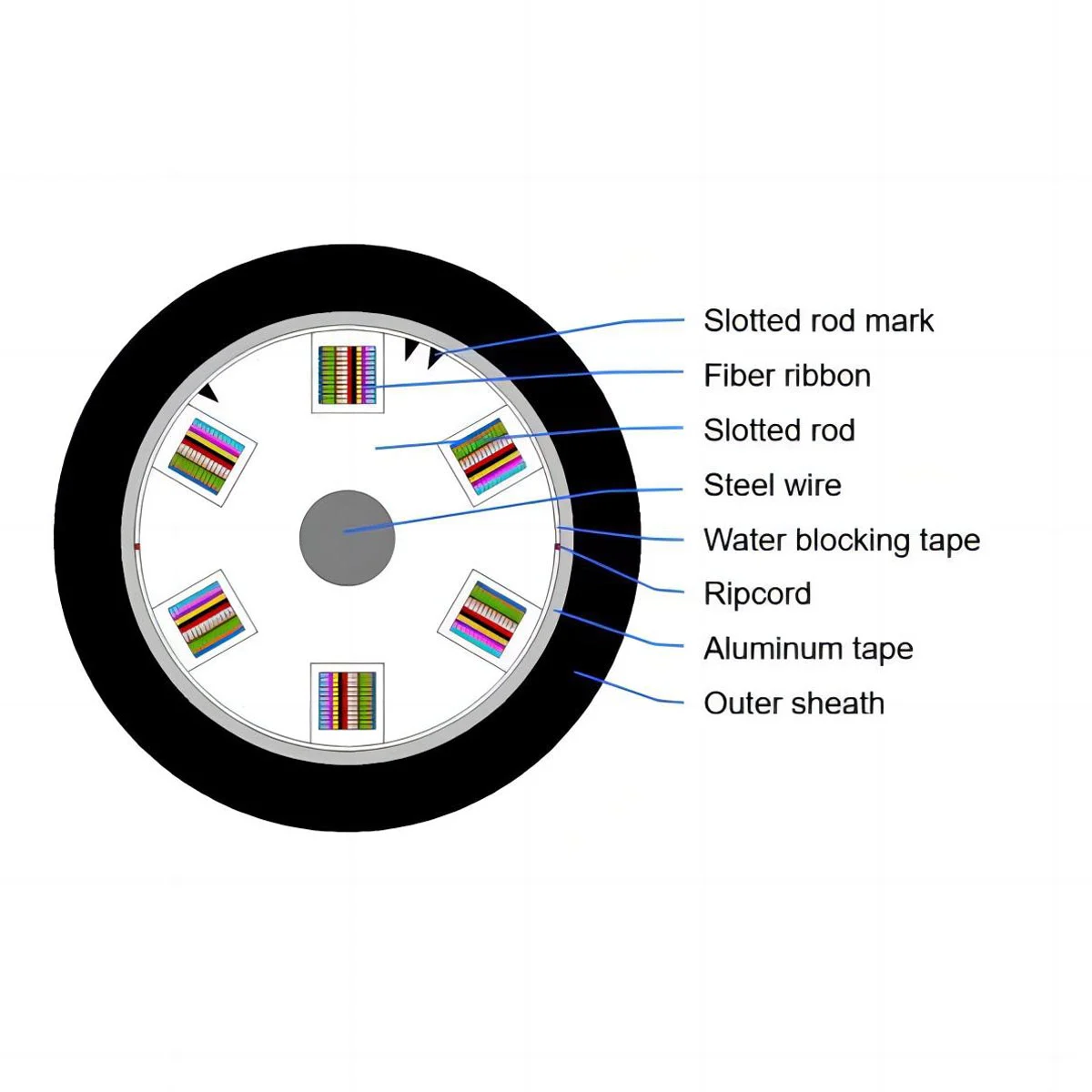

After being positioned parallel, the fibers are cooted together.to create a ribbon of fiber.

The cable core is made up of slots that include a central strength element for the fiber ribbons. Water-blocking tape and laminated aluminum tape are used to cover the core longitudinally. A polyethylene sheath layer is then extruded.

The cable's uniquely designed construction offers superior optical and mechanical performance.

The Gel-free Water Blocking technology is environmentally friendly and increases installation efficiency.

Low weight and high fiber density.

Mass fusion splice suit.

After the cable is stripped, it is simple to mid-span.

30 years of product life.

| Fiber Ribbon | Fiber Count | Number of frame slot | Maximum Fiber Count of each fiber ribbon | Nominal Diameter (mm) | Nominal Weight (kg/km) | Allowable Tensile Load(N) (Short term/long term) | Allowable Crush Resistance (N/10cm) (Short term/long term) |

4 Fiber Ribbon | 24 | 3 | 2 | 11.0 | 101 | 3000/1000 | 3000/1000 |

60 | 5 | 4 | 12.0 | 113 | 3000/1000 | 3000/1000 | |

100 | 5 | 5 | 13.7 | 144 | 3000/1000 | 3000/1000 | |

200 | 10 | 5 | 15.7 | 214 | 3000/1000 | 3000/1000 | |

300 | 15 | 5 | 20.3 | 322 | 3000/1000 | 3000/1000 | |

6 Fiber Ribbon | 72 | 3 | 4 | 12.6 | 140 | 3000/1000 | 3000/1000 |

96 | 4 | 4 | 12.6 | 140 | 3000/1000 | 3000/1000 | |

120 | 5 | 4 | 13.8 | 146 | 3000/1000 | 3000/1000 | |

144 | 6 | 4 | 14.2 | 155 | 3000/1000 | 3000/1000 | |

216 | 6 | 6 | 17.0 | 240 | 3000/1000 | 3000/1000 | |

288 | 8 | 6 | 17.7 | 258 | 3000/1000 | 3000/1000 | |

384 | 8 | 8 | 20.2 | 350 | 3000/1000 | 3000/1000 | |

432 | 9 | 8 | 21.2 | 378 | 3000/1000 | 3000/1000 |