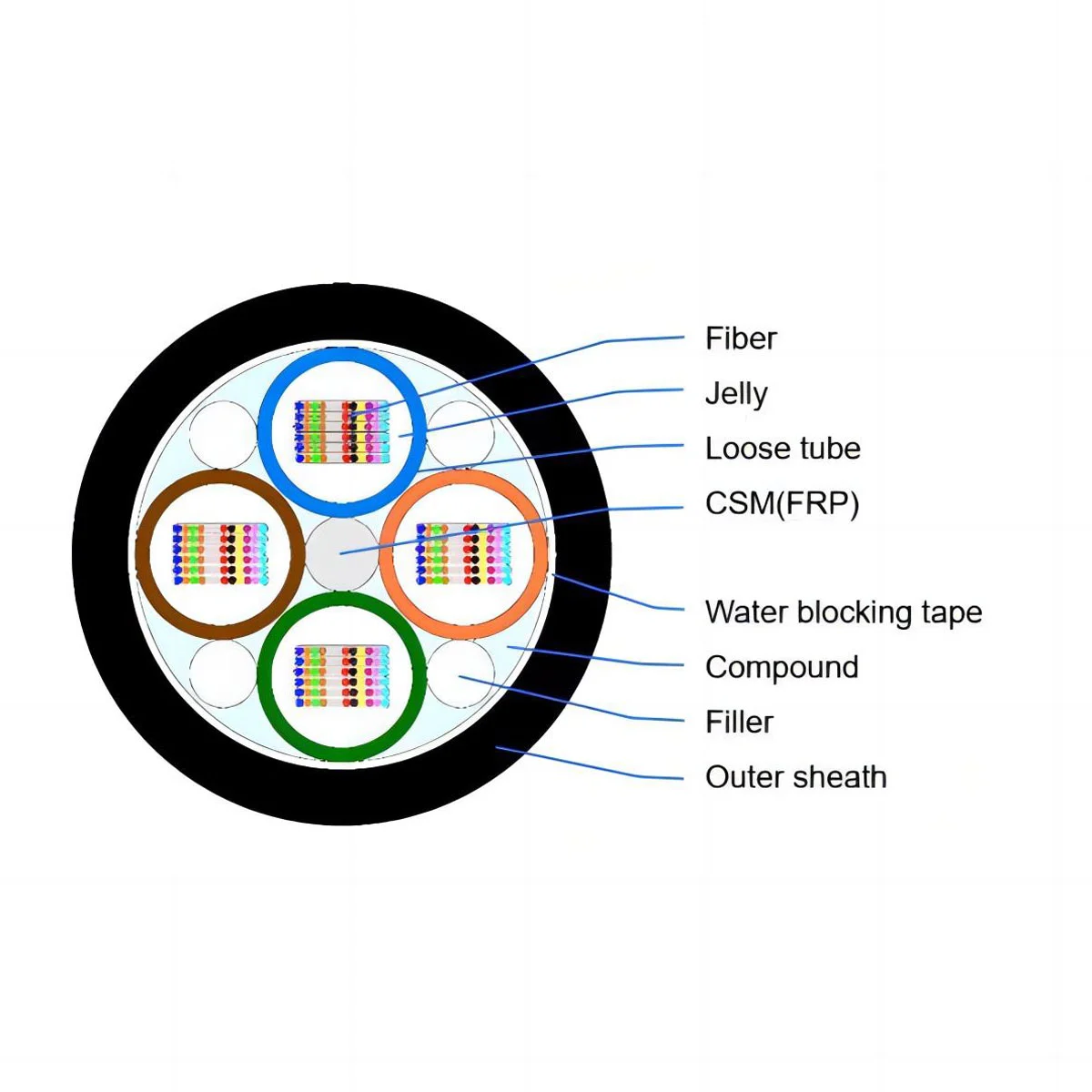

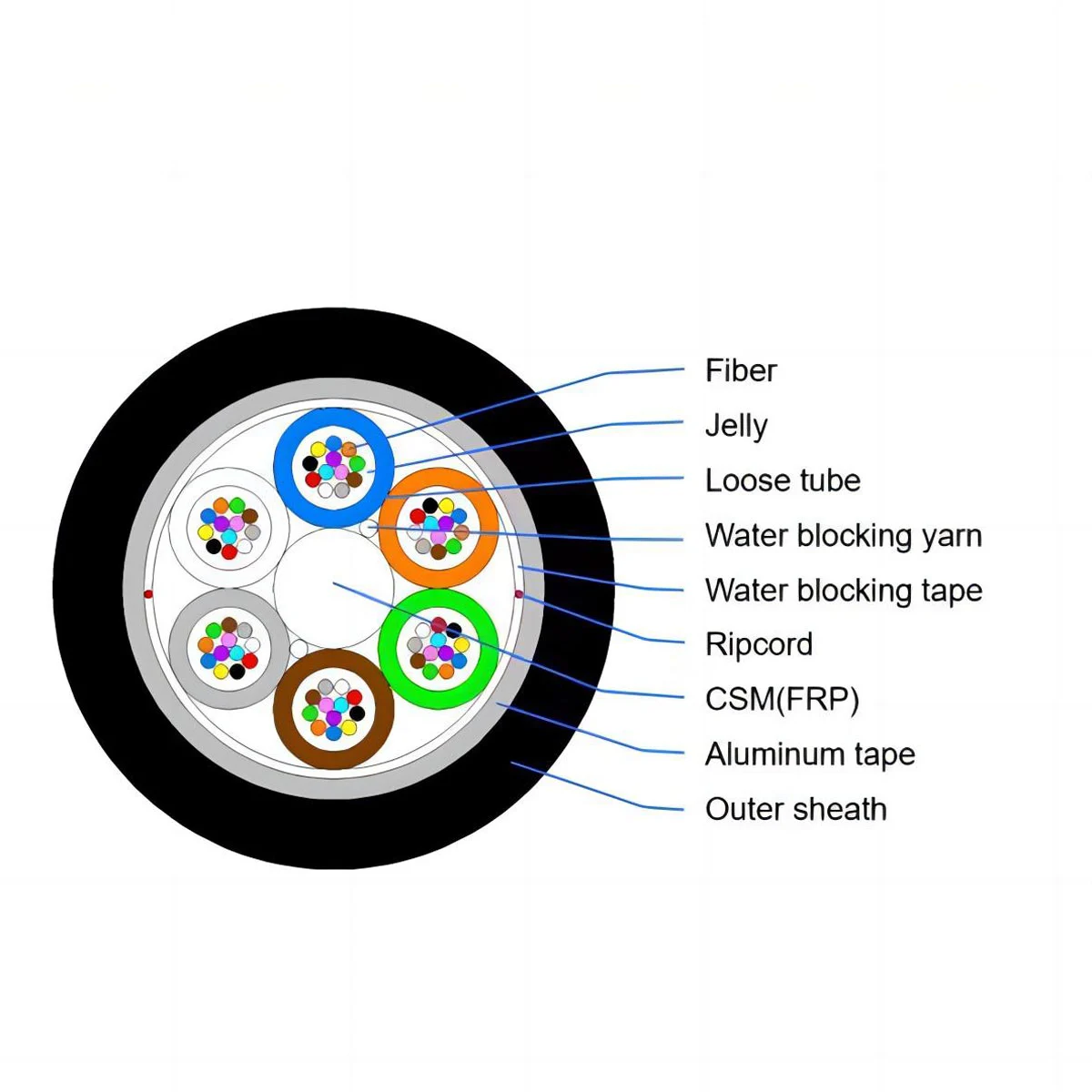

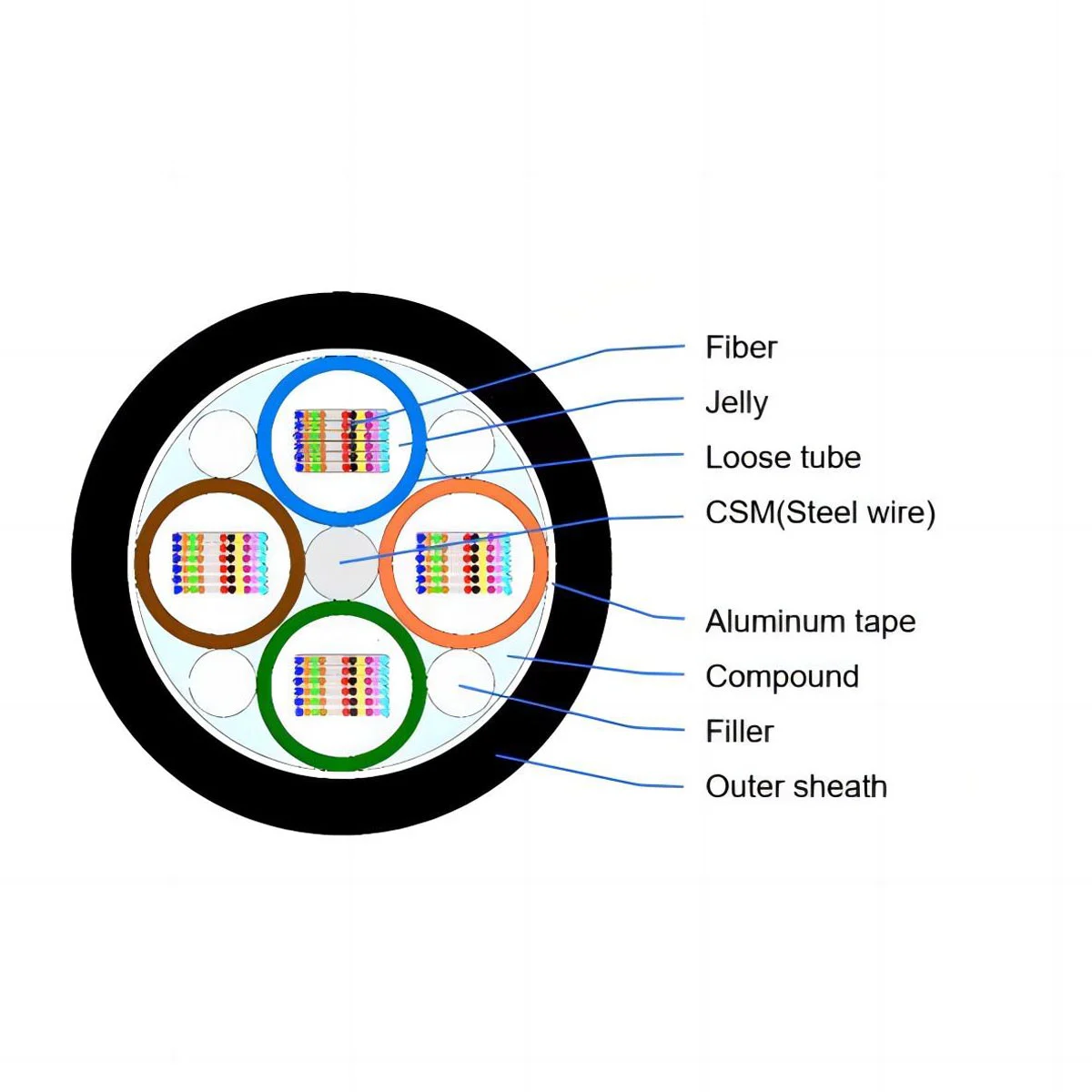

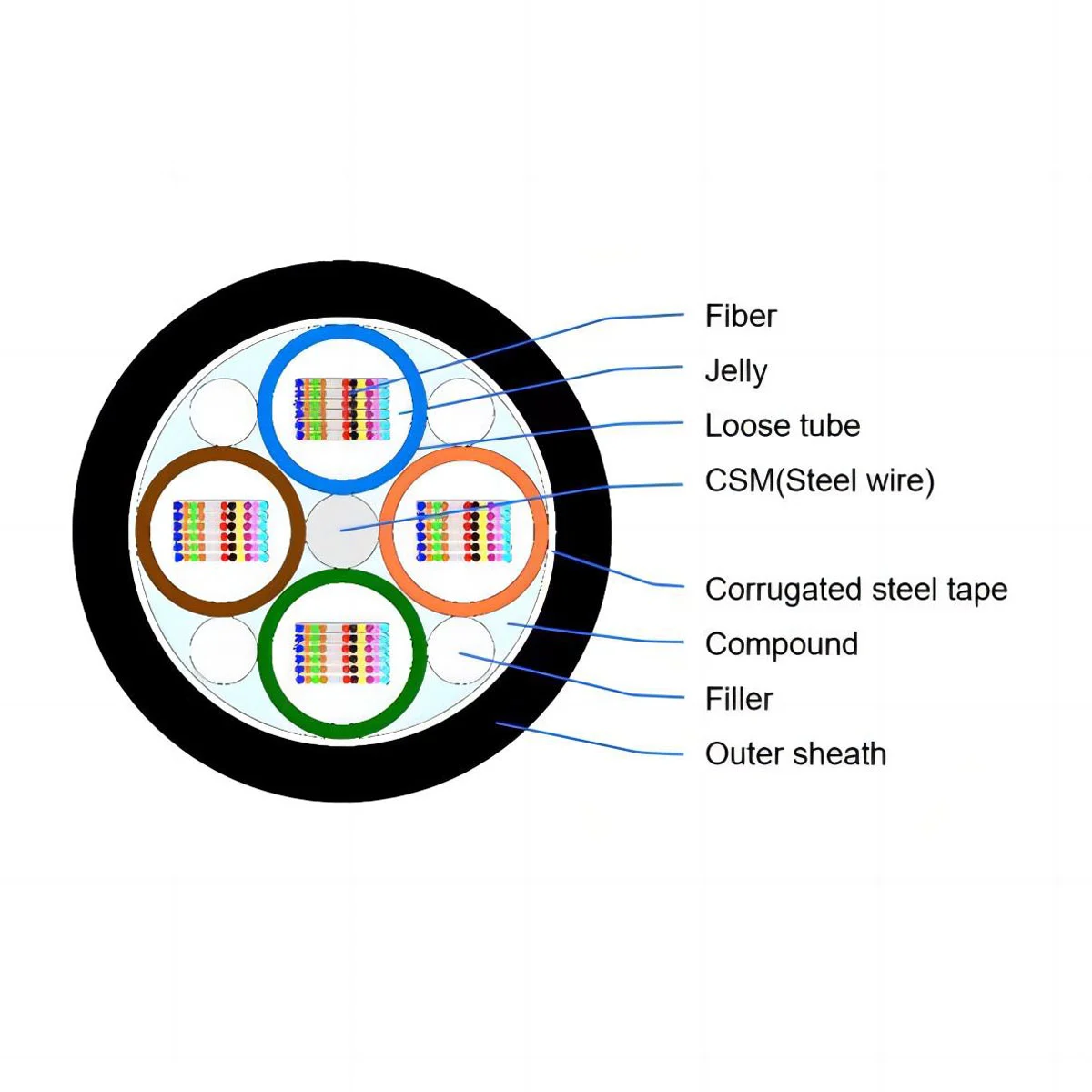

In a loose, high-modulus plastic tube, the fiber ribbons are positioned. The tubes are filled with a water-resistant filling substance to fill the interstice on the inside and exterior. In the middle of the core is a fiber-reinforced plastic rod that, if needed, is coated with polyethylene to provide strength.

A compact, spherical cable core is created by stranding tubers (and fillers) around the strength member. Lastly, to create a cable, a layer of polyethylene sheath is extruded.

Good moisture-proof and water-resistant performance is provided by the full section water blocking structure.

Ideal optical fiber protection is provided by special filling gel-filled loose tubes.

A core strength member is a dielectric FRP rod with a high modulus.

High fiber density, cost-effective, easy to identify and maintain, and convenient for installation.

It is simple to route the flexible buffer tubes in closures.

Outstanding temperature and mechanical performance.

Superior protection against UV rays, fungi, abrasions, and other outdoor elements is offered by jackets.

A 30-year lifetime is made possible by strict workmanship and raw material management.

| Fiber Ribbon | Fiber Count | No. of | Max Ribbonrs Per Tube | Nominal Diameler (mm) | Nominal Weight (kg/km) | Allowable Tensile Load(N) (Short term/long term) | Allowable Crush Resistance(N/10cm) (Short term/long term) |

6-Fiber Ribbon | 12~120 | 5 | 4 | 14.0 | 236 | 1500/600 | 1000/300 |

126~180 | 5 | 6 | 14.0 | 236 | |||

186~288 | 6 | 6 | 18.2 | 364 | 2200/600 | ||

12-Fiber Ribbon | 24~360 | 5 | 6 | 18.2 | 324 | 2200/600 | 1000/300 |

372~576 | 5 | 12 | 21.3 | 450 | |||

>600 | customized | ||||||

Special cable structure can be designed and manufactured on customer's request.