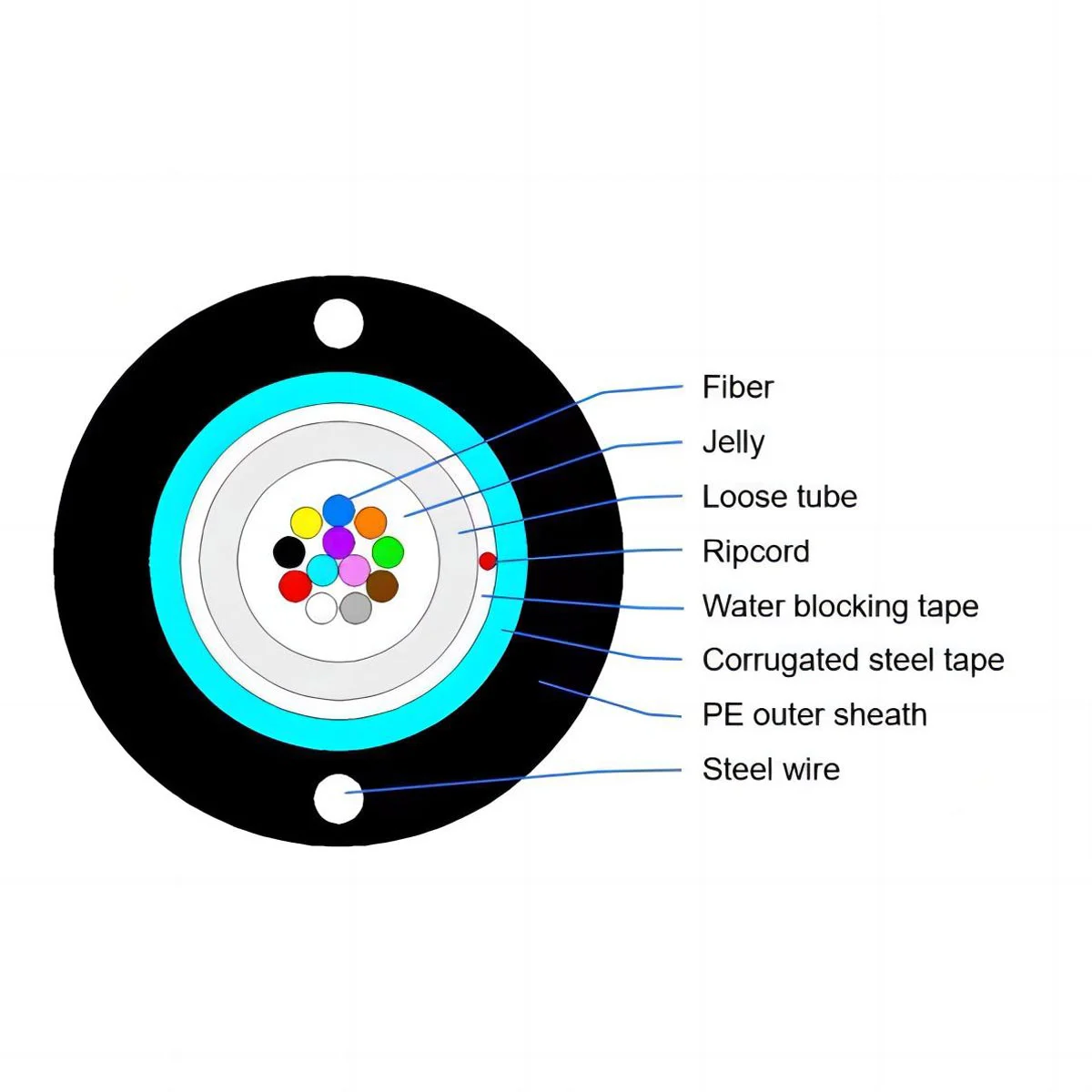

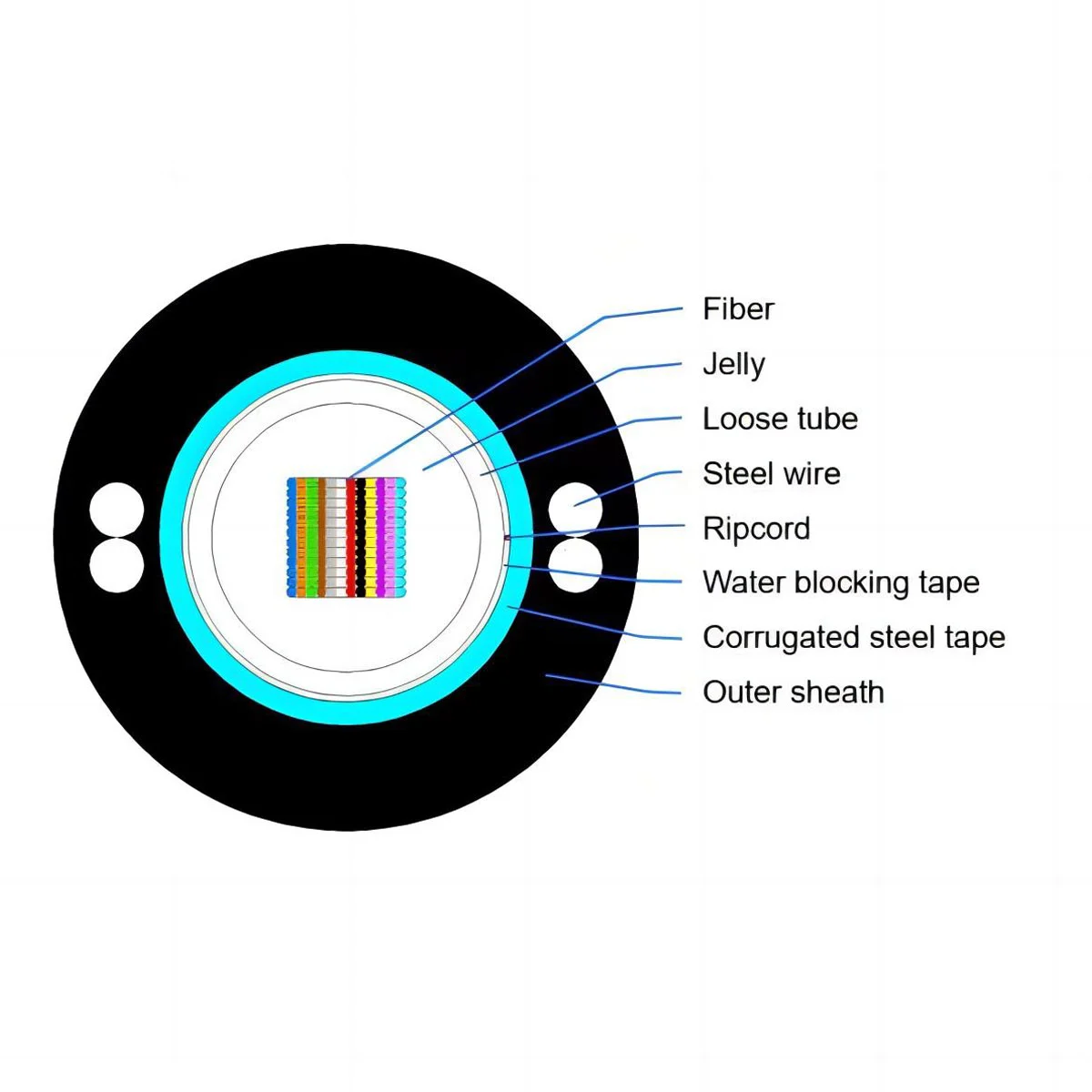

The fibers are arranged in a loose, high-modulus plastic tube. A filling material that is resistant to water is poured into the tube. One layer of coated steel tape is applied longitudinally around the tube.

On either side of the steel tape are two steel wires that are paralleled. To ensure UV protection, the polyethylene sheath is extruded outside the tube and strength components.

Complete section water blocking construction offers excellent moisture-proof and water-blocking performance.

loose tubes with special filling gel filling offer ideal optical fiber protection.

Desired tensile strength and crush resistance are provided by two parallel steel wires.

Ideal for CATV networks, interoffice connections, and access networks (particularly FTTC and FTTB).

A 30-year lifetime is made possible by strict workmanship and raw material management.

Fiber Number | Nominal diameter | Nominal weight | Allowable tensile load (N) | Allowable crush resistance (N/10cm) |

2~12 | 9.4 | 95 | 1500/600 | 1000/300 |

>12 | Available upon customers' request | |||