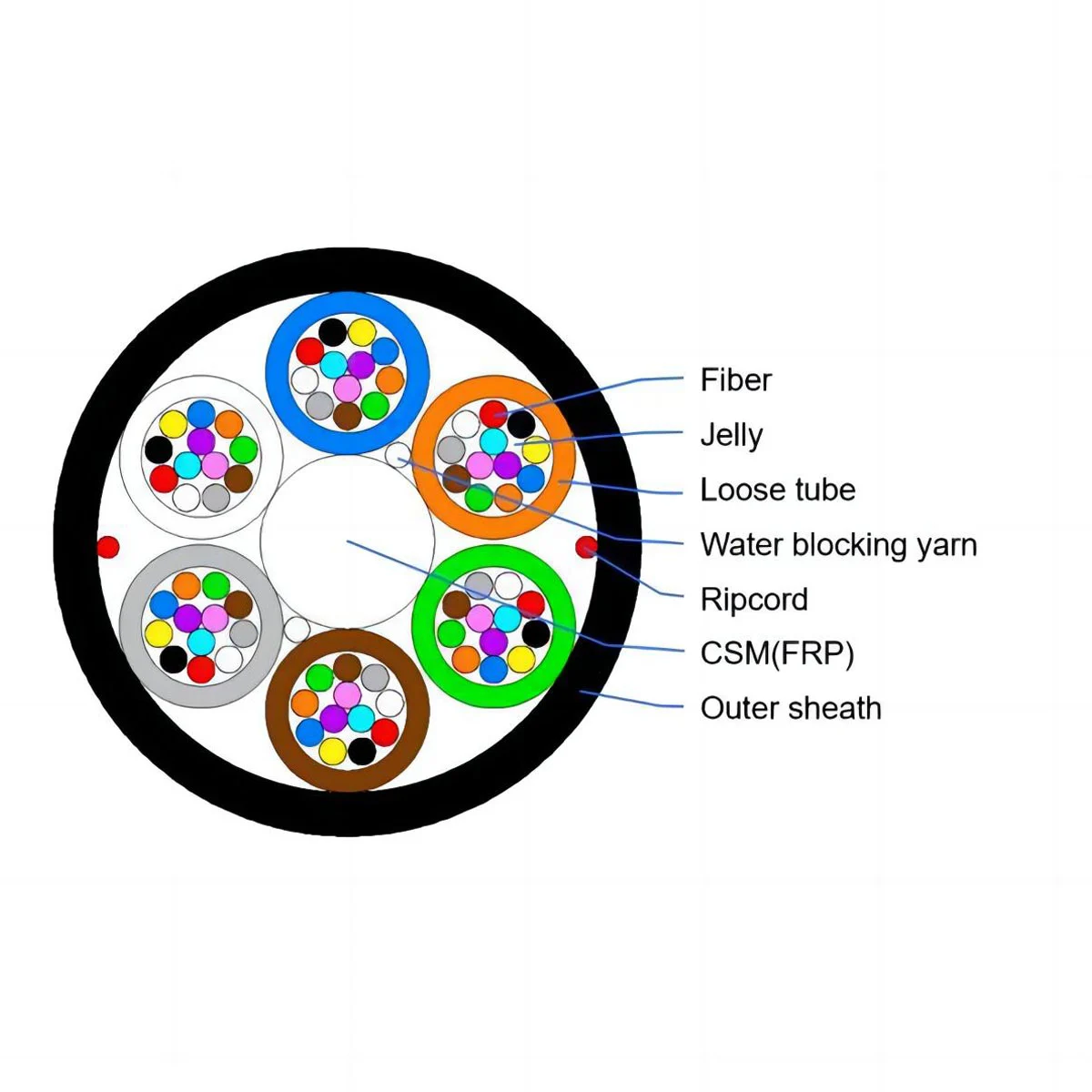

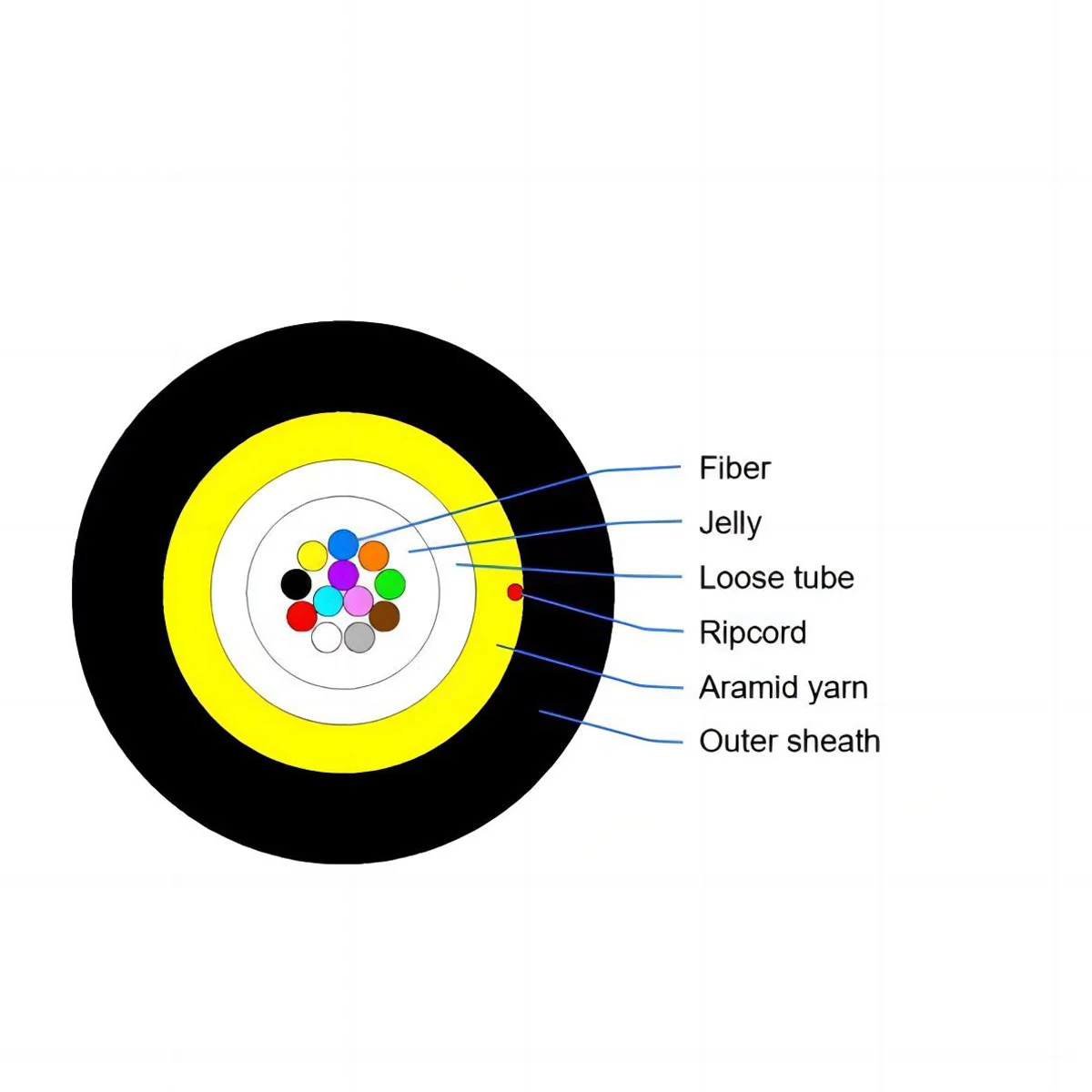

The fibers are placed within a loose, jelly-filled tube composed of high modulus plastic. As a strength member, a fiber reinforced plastic rod (FRP), coated with polyethylene if needed, is positioned in the middle of the core.

To create a small, spherical cable core, tubers (and fillers) are stranded around the strength member. To create a cable, a thin layer of polyethylene sheath is extruded around the cable core.

High fiber density, compact dimension, and low weight.

Fit for installation by air blowing.

Outstanding temperature performance for applications in a variety of temperature environments.

Fiber Count | Nominal Diameter (mm) | Nominal Weight (kg/km) | Allowable Tensile(N) | Minimum Bending Radius(mm) | Allowable Crusl Resistant (N/10cm) | ||

Short term | Long term | Dynamic | Static | ||||

2~72 | 5.4 | 26 | 0.3G | 1G | 20D | 10D | 500 |

96 | 6.3 | 38 | 0.3G | 1G | 20D | 10D | 500 |

144 | 8.0 | 37 | 0.3G | 1G | 20D | 10D | 500 |

192 | 10.0 | 60 | 0.3G | 1G | 20D | 10D | 500 |

216 | 10.0 | 60 | 0.3G | 1G | 20D | 10D | 500 |

288 | 10.6 | 78 | 0.3G | 1G | 20D | 10D | 500 |

Special cables structures can be designed and manufactured on customer's request.