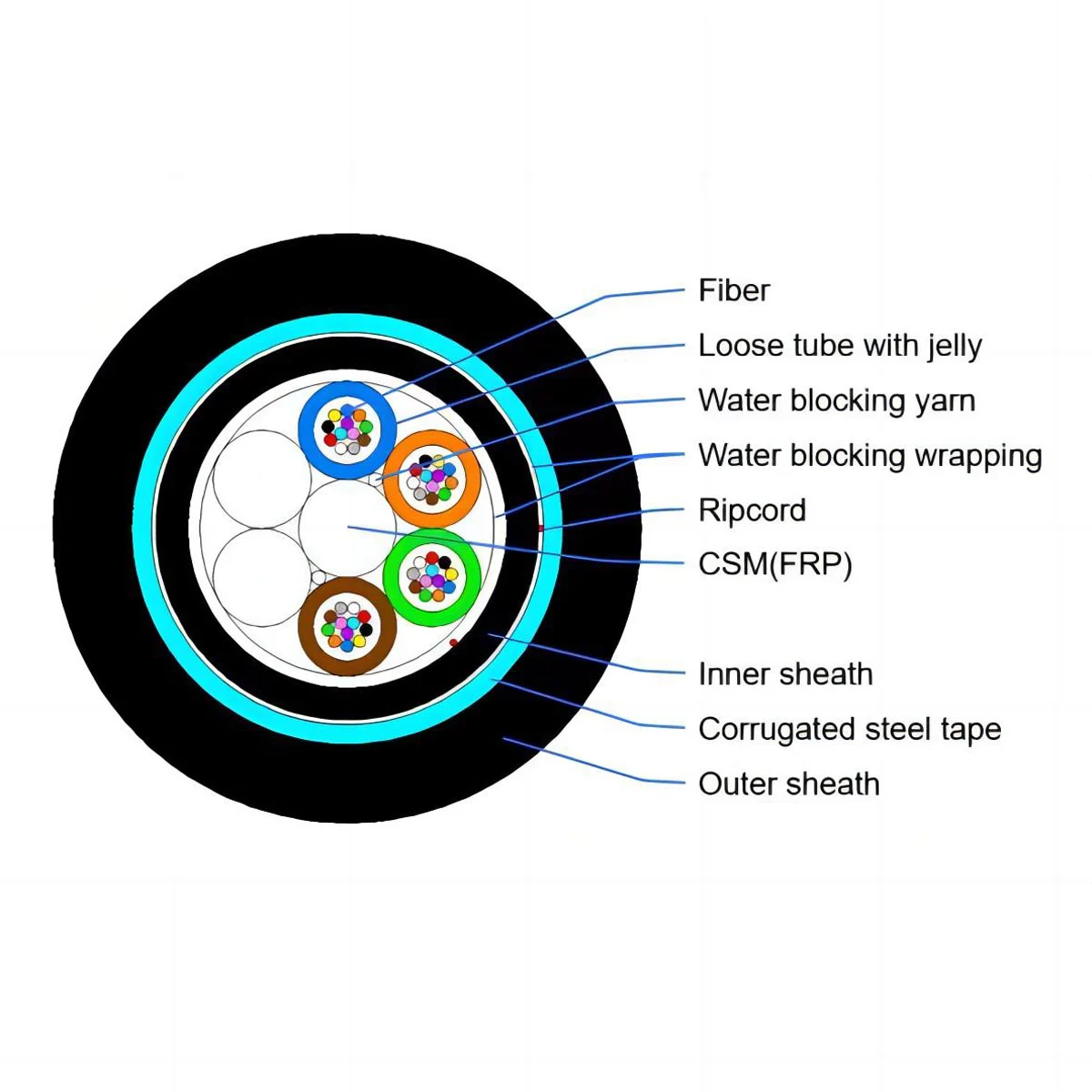

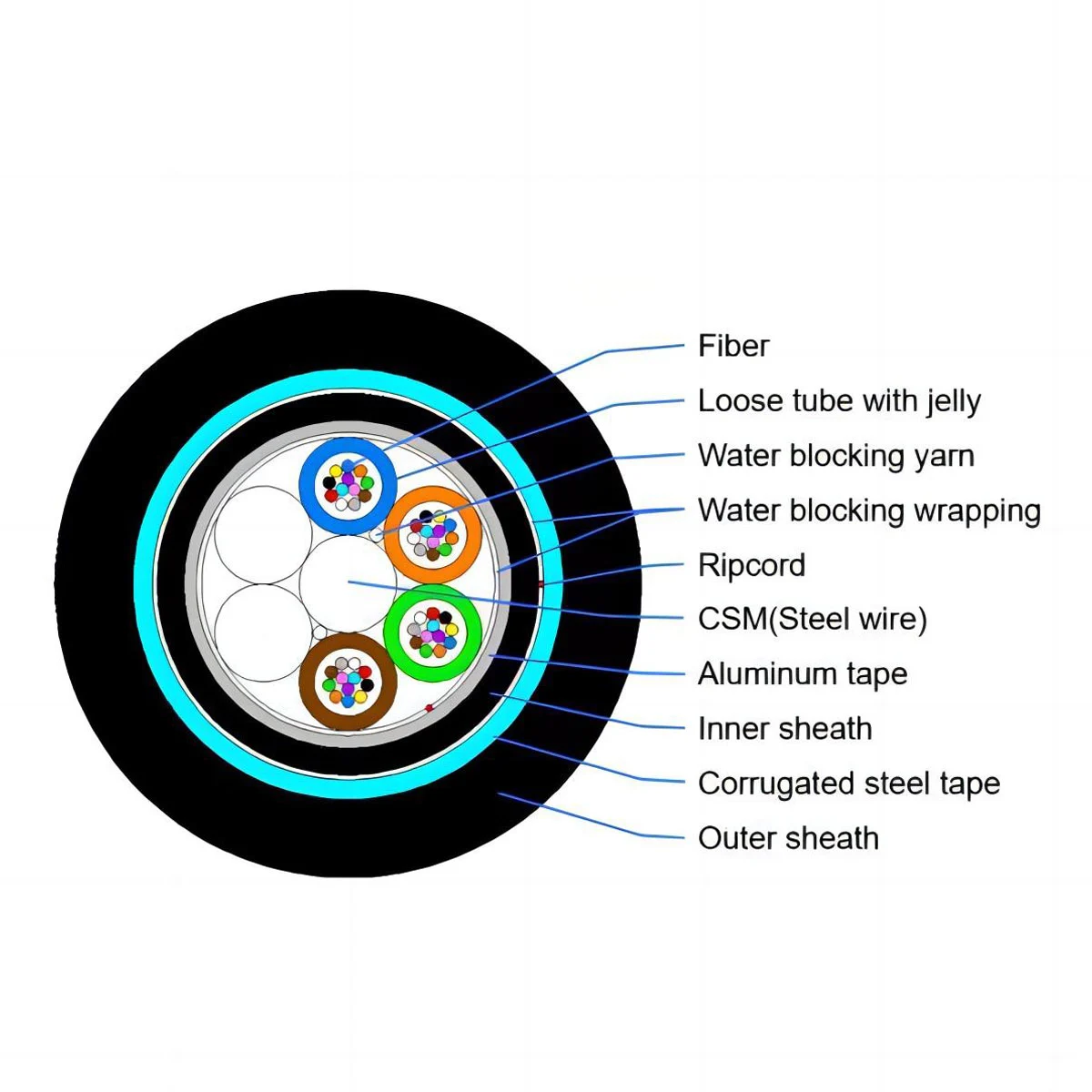

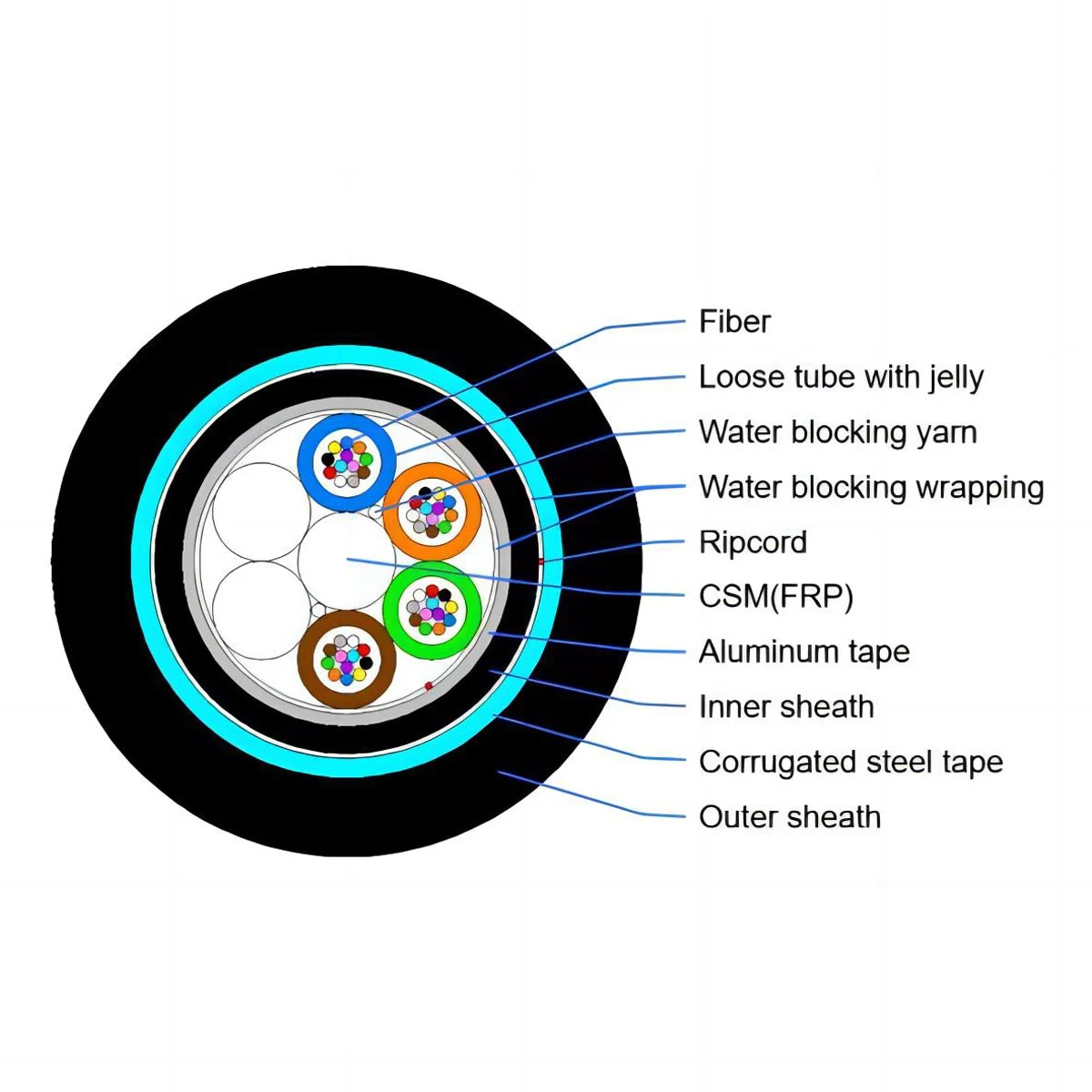

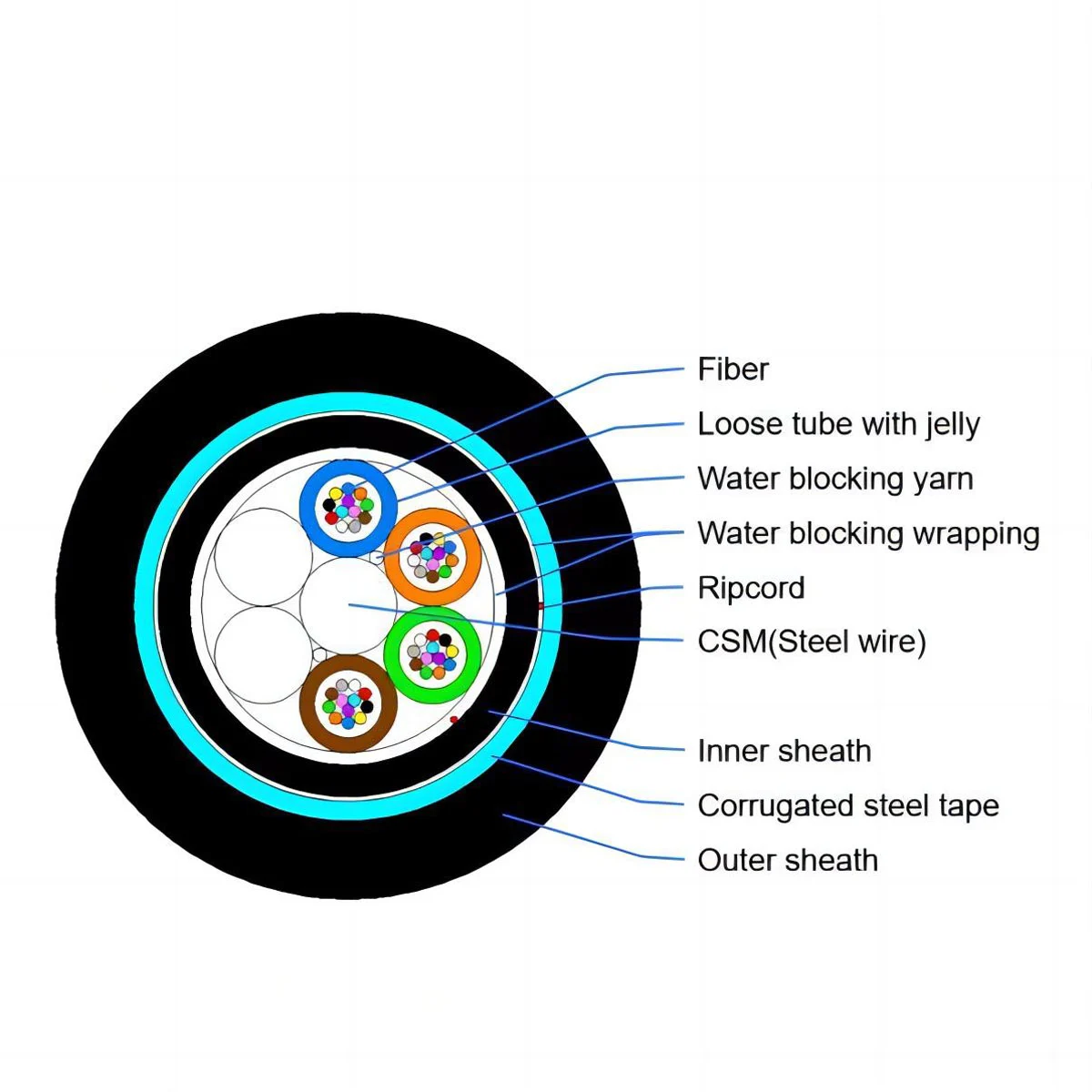

The fibers are arranged in loose, high modulus plastic tubers. A chemical that blocks water is poured into the tubes. The strength member is the dielectric fiber-reinforced plastic rod, which is positioned in the center of the core and may be coated with polyethylene if needed. The cable core is formed by stranding tubes around the strength component.

As an inner sheath, a layer of polyethylene is extruded. The cable is finished with the PE outer sheath once the PSP has been put longitudinally over the inner sheath.

Every carefully chosen water-blocking structure offers good moisture-proof and water-blocking performance.

Perfect shielding for optical fibers is provided by special filling gel-filled loose tubes.

Reinforced plastic (FRP) with a high Young's modulus is a key component of strength.

Armoured longitudinal corrugated steel tape offers dependable moisture-proof performance and excellent crush resistance.

Areas with regular illumination might use FRP central strength members.

A 30-year lifetime is made possible by strict workmanship and raw material management.

Fiber count | Nominal diameter | Nominal weight | Max fiber per tube | NO.OF (Tubes +filler) | Allowable tensile load (N) | Allowable crush resistance (N/10cm) |

2~42 | 14.1 | 193 | 6 | 7 | 2700/1000 | 3000/1000 |

44~72 | 15.1 | 212 | 12 | 6 | 2700/1000 | 3000/1000 |

74~96 | 16.3 | 246 | 12 | 8 | 2700/1000 | 3000/1000 |

98~120 | 17.8 | 288 | 12 | 10 | 3000/1000 | 3000/1000 |

122~144 | 19.4 | 336 | 12 | 12 | 3000/1000 | 3000/1000 |

>144 | Available upon customer's request | |||||